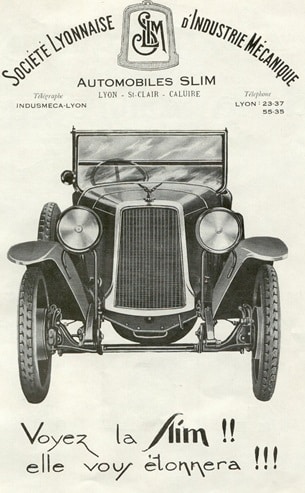

Creation of the company in 1926

In the early 1900s, the city of Lyon was renowned for its mechanical industry. It was at this time that SLIM (Société Lyonnaise d’Industrie Mécanique) started its activity by manufacturing engines and complete cars.

In 1926, one of the shareholders of SLIM decided to create his own company. He reversed the name which would become MIL’S (Manufacture Industrielle Lyonnaise de Surpresseurs) and attracted his former collaborators in this industrial adventure.

First compressed air compressors for industry

Building on the experience acquired in the design of thermal engines, Adolphe THEVENIN designed the first piston compressors for compressed air, which at the time were also used as a vacuum pump. The first applications of compressed air and vacuum were industrial

The development of a range for medical vacuum

From 1970, MIL’S became interested in the health market and developed a specific range of vacuum and breathing air systems. The 4th family generation is currently involved in the management of the company which has developed internationally since the 2000s.

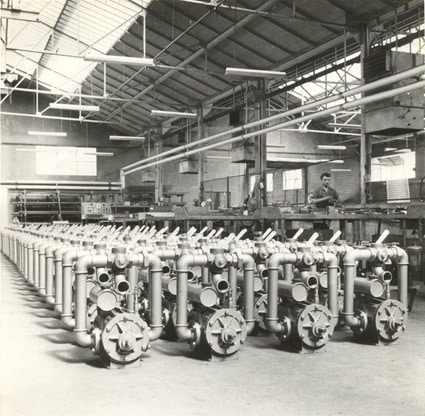

New premises dedicated to production

In 2014, the company expanded its production site located in Genas. It is thus made up of two centers with a total surface area of 12,500 m²; one for the machining and assembly of pumps, another dedicated to the assembly of industrial and medical systems.

In addition to the machining workshop and vacuum pump assembly lines, these new premises also accommodate testing rooms as well as a design office dedicated to pump design. This new factory allows MIL’S to increase its production capacity in response to progressive changes in demands.

Integration of a boilermaker

In 2016, the vacuum pump machining and assembly division integrated an industrial boilermaker.

With this new know-how, MIL’S will be able to gain flexibility and improve its manufacturing times for industrial vacuum systems and medical packages, which allows complete control of the manufacturing process.